Factory For 110t H Type Double Point Press Machine - C Frame High Speed Press – Daya

Factory For 110t H Type Double Point Press Machine - C Frame High Speed Press – Daya Detail:

Performance characteristics

1. The frame is made of high-strength cast iron. After internal stress relief, the material is stable and the precision remains unchanged, which is most suitable for continuous stamping production;

2. Double guide rail, one center pillar structure, using zero error ball bearing to replace the traditional sliding plate structure, so as to reduce the dynamic friction to the minimum, and cooperate with forced lubrication to minimize the thermal deformation and achieve the highest accuracy;

3. The reverse side dynamic balance device is optional to reduce vibration, so that the press has the best accuracy and stability;

4. Manual mold adjustment, with mold height display and oil pressure locking device, is convenient for mold adjustment operation;

5. Man machine interface microcomputer control, numerical fault monitoring system screen display, easy to operate;

Specification

Advantages

Slide guide

Advantage 1: The slide rail adopts “high frequency quenching” and “rail grinding process”:

High frequency quenching: the hardness reaches above hrc48,

Rail grinding process: the surface finish can reach Ra0.4, the flatness is as high as 0.01mm/m2, which is generally 03mm / m2.

Advantages: small wear, high precision, long time to maintain precision and improve the service life of the die.

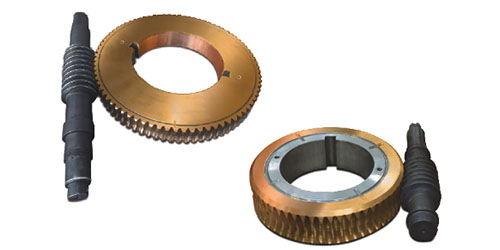

Worm gear

Advantage 2: Turbine with high adjustment of slide die adopts high strength copper alloy material: Tin Phosphorus Bronze (zqsn10-1)

Compared with the ball seat of nodular cast iron used by general factories

Advantages: the strength and wear resistance are improved correspondingly. The probability of seizure is greatly reduced in the process of die adjustment, Extended service life

Ball socket

Advantage 3: Ball seat material: sintered TM-3 copper alloy ball seat, ball socket of general manufacturer is nodular cast iron.

Advantages: the high-strength TM-3 copper alloy ball seat has a surface compressive strength of 1000kgf / C m2. In the process of stamping, the probability of seizure is greatly reduced and the service life is prolonged

Copper sleeve

Advantage 4: All copper sleeves of punch press are made of Tin Phosphorus Bronze zqsn10-1, and bc6 (zqsn 6-6-3) copper material is used by general manufacturers

Advantages: the strength is 1.5 times higher than that of bc6 copper, with high strength, small wear and long precision retention time

Thimble

Advantage 5: Sleeve ring, ring in contact with oil seal, ring “surface grinding” + “surface chromium plating (CR)” process

Advantages: the surface finish is between Ra0.4 and Ra0.8, it is not easy to leak oil when contacting with oil seal, and the surface is chromium plated (CR)

Process, hardness as high as hrc48 degrees, to ensure long-term use does not wear, oil seal service life is longer

Crankshaft

Advantage 6: The crankshaft is made of high strength alloy 42CrMo, and the crankshaft of general manufacturers is made of 45 steel

Advantages: the strength is 1.3 times higher than that of 45 steel, the service life is longer, and the probability of breaking crankshaft is greatly reduced (strictly through forging, heat treatment, flaw detection, processing, inspection, etc.) to ensure All kinds of quality problems in the production process of crankshaft are avoided to ensure the quality of crankshaft.

Tubing

Advantage 7: The standard machine open single point and open double point crank punch press, the standard oil pressure lubrication piping adopts Φ 6 (other manufacturers generally adopt Φ 4), medium and large punch press oil pressure lubrication pipe adopts Φ 8

Advantages: long pipeline, large diameter is not easy to block, break, ensure the safety of lubricating oil, smooth

Gear & drive shaft

Advantage 8: The gear shaft adopts high frequency quenching process to ensure long service life without wear and tear

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Factory For 110t H Type Double Point Press Machine - C Frame High Speed Press – Daya , The product will supply to all over the world, such as: Costa Rica, Poland, Latvia, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!