Straight Side Unitized Frame Double Crank Servo Press Machine(STE-Series)

Main performance characteristics:

Main performance characteristics I:

1 ® High strength body structure, small deformation and high precision

2 ® The sliding block adopts 4 angle 8 face guide rail, and the sliding block guide rail adopts "high-frequency quenching" and "rail grinding process": low wear, high precision, long precision holding time, and improves the service life of the mold.

3 ® The crankshaft is made of high-strength alloy material 42CrMo. Its strength is 1.3 times that of 45 steel and its service life is longer.

4 ® The copper sleeve is made of tin phosphor bronze ZQSn10-1, and its strength is 1.5 times that of ordinary BC6 brass.

5 ® The use of highly sensitive hydraulic overload protection device can effectively protect the service life of the punch and die.

6 ® Standard Japanese SMC pressure regulating valve, lubricator, air filter.

7 ® The standard configuration is high-precision bearing and Japanese NOK seal.

8 ® 15.6 inch touch screen

9 ® Optional mold pad (air cushion).

10 ® The forced thin oil circulating lubrication device is adopted, which is energy-saving, environment-friendly, and has an automatic alarm function. The stamping speed can be increased by adjusting the amount of oil.

Main performance characteristics II:

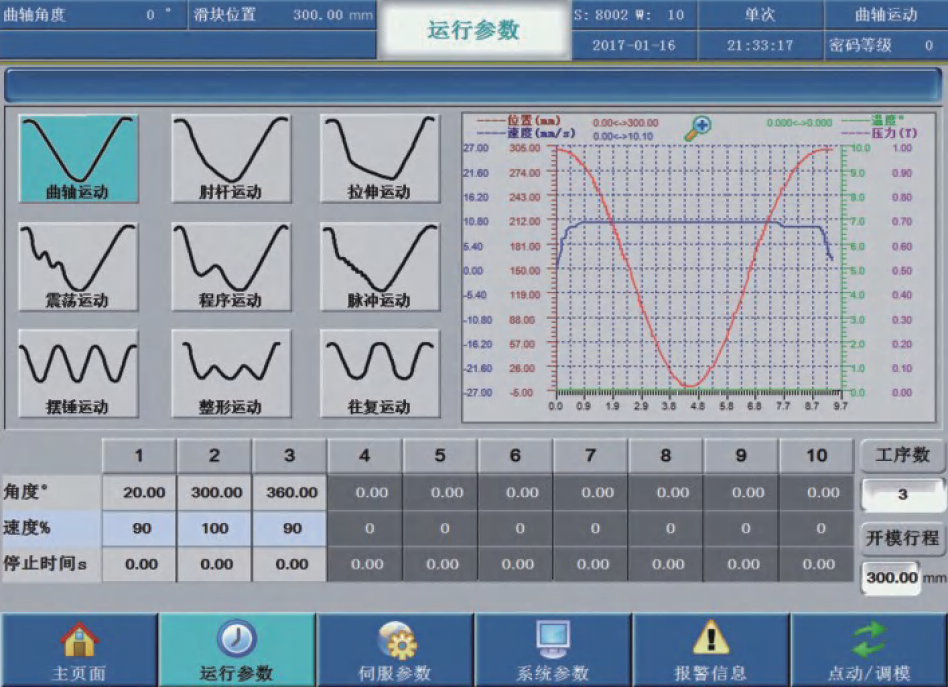

1 ® 9 processing modes are built-in, and each product can select the processing curve most suitable for component processing,So as to achieve high precision, high efficiency and high energy conservation.

2 ® Compared with traditional presses, it has simple structure, high mechanical transmission efficiency and low maintenance cost.

3 ® According to the characteristics of products/materials, the stamping forming speed can be reduced during the material processing to achieve the best forming speed of products/materials. Thus reducing vibration and stamping noise; Improve product accuracy and extend the service life of the mold.

4 ® According to different products, different heights are required. The stroke of the punch can be set arbitrarily, which greatly shortens the stamping time and improves the efficiency.

Standard configuration

|

1 |

Hydraulic overload protection device |

9 |

Air blowing device |

|

2 |

Servo motor(Adjustable speed) |

10 |

Independent control cabinet |

|

3 |

Digital die height indicator |

11 |

Mis-delivery detection device reserved interface |

|

4 |

Slider and mold balance device |

12 |

Photoelectric safety protection device |

|

5 |

Electronic cam switch device |

13 |

Oil-gathering silencer |

|

6 |

Prejudging counter |

14 |

Electric grease lubrication device |

|

7 |

Air source connector |

15 |

Touch (pre-break, prejudge, total count) |

|

8 |

Second falling protection device |

16 |

Air cooled chiller |

Optional Configuration

|

1 |

Pneumatic mold pad device |

5 |

Feeder (air, mechanical and NC) |

|

2 |

Thin oil lubrication device |

6 |

Leveling machine |

|

3 |

Quick die change device (Die lifter, die clamper or die mover) |

7 |

Rack |

|

4 |

Upper part hit material device of slider |

8 |

Manipulator |

Technical parameter

| Name | Unit | STE-160sv | STE-200sv | STE-250sv | STE-300sv | STE-400sv | STE-500sv | STE-600sv | STE-800sv |

| Press capacity | Ton | 160 | 200 | 250 | 300 | 400 | 500 | 600 | 600 |

| Impact force location | mm | 6 | 6 | 7 | 7 | 7 | 8 | 10 | 10 |

| Slider strokes per minute(S.P.M) | Swing mode | ~100 | ~100 | ~75 | ~70 | ~60 | ~60 | ~60 | ~50 |

| Full stroke | ~55 | ~45 | ~40 | ~40 | ~30 | ~30 | ~30 | ~25 | |

| Slider stroke length | mm | 200 | 200 | 250 | 300 | 300 | 300 | 300 | 350 |

| Max mold height | mm | 450 | 500 | 550 | 550 | 550 | 600 | 600 | 800 |

| Slider adjustment amount | mm | 100 | 120 | 120 | 120 | 120 | 150 | 150 | 150 |

| Up platform size | mm | 1600*650 | 1850*750 | 2100*900 | 2100*900 | 2200*900 | 2500*1000 | 2800*1200 | 3400*1400 |

| Down platform size | mm | 1800*760 | 2200*940 | 2500*1000 | 2500*100 | 2500*1000 | 2800*1100 | 3000*1200 | 3600*1400 |

| Side opening | mm | 700*450 | 700*600 | 700*600 | 900*650 | 900*650 | 1000*700 | 1100*700 | 1200*700 |

| Servo motor torque | NM | 10000 | 14000 | 15000 | 21000 | 32000 | 40000 | 60000 | 65000 |

| Air pressure | kg*cm² | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Press accuracy grade | Grade | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 |