Products

-

TNCF3-series 3IN1 NC Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

TNCF4-series 3IN1 NC Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

TNCF5-series 3IN1 NC Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

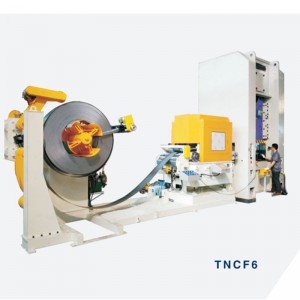

TNCF6-series 3IN1 NC Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

TNCF7-series 3IN1 NC Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

JNCF-series-3IN1 NC Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

SAF-A-series Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo... -

SAF-B-series Servo Feeder Machine

Characteristic 1. Leveling adjustment adopts electronic digital display meter reading; 2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment; 3. The height of feeding line is adjusted by motor driven elevator; 4. A pair of hollow roller blocking device is used for material sheet; 5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment); 6. Hydraulic pressing arm device; 7. The gear mo...