Factory Free sample 80t Screen Mesh Stamping Punch Machine - Stamping Die – Daya

Factory Free sample 80t Screen Mesh Stamping Punch Machine - Stamping Die – Daya Detail:

Classification

There are many forms of stamping dies, which are classified according to the working nature, die structure and die material.

Classification according to process properties

a. A die that separates material along a closed or open contour. Such as blanking die, punching die, cutting die, cutting die, trimming die, cutting die, etc.

b. The bending die makes the blank or other blank along the straight line (bending curve) to produce bending deformation, so as to obtain a certain angle and shape of the workpiece mold.

c. Deep drawing die is a kind of die which can make the blank of sheet metal into open hollow parts, or make the hollow parts further change the shape and size.

d. The forming die is a kind of die which directly copies the blank or semi-finished workpiece according to the shape of the punch and die in the drawing, while the material itself only produces local plastic deformation. Such as bulging die, necking die, expanding die, undulating forming die, flanging die, shaping die, etc.

e. Riveting die is to use external force to make the parts join or lap together in a certain order and way, and then form a whole

Classification according to process combination degree

a. Single process die in a press stroke, only one stamping process of the die.

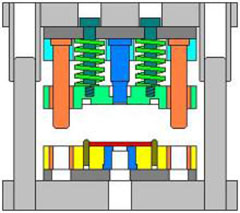

b. The compound die has only one station, and it can complete two or more stamping processes at the same station in one stroke of the press.

c. Progressive die (also known as continuous die) has two or more positions in the feeding direction of the blank. In one stroke of the press, two or more stamping processes are completed in different positions.

d. The transfer die integrates the characteristics of single process die and progressive die. By using the manipulator transfer system, the product can be quickly transferred in the mold. It can greatly improve the production efficiency of the product, reduce the production cost of the product, save the material cost, and the quality is stable and reliable.

Classification by product processing method

According to the different processing methods, the dies can be divided into five categories: punching and shearing die, bending die, drawing die, forming die and compression die.

a. Punching and shearing die: the work is completed by shearing. The commonly used forms are shearing die, blanking die, punching die, trimming die, trimming die, trimming die, punching die, broaching die and punching die.

b. Bending die: it is to bend the flat embryo into an angle shape. Depending on the shape, accuracy and production capacity of the parts, there are many different forms of dies, such as ordinary bending die, cam bending die, curling die, arc bending die, bending punching die and twisting die, etc.

c. Drawing mould: drawing mould is to make the flat rough embryo into seamless container with bottom.

d. Forming die: refers to the use of a variety of local deformation methods to change the shape of the burr, its forms are convex forming die, crimping forming die, necking forming die, hole flange forming die and circular edge forming die.

e. Compression die: it is to use the strong pressure to make the metal rough embryo flow and deform into the required shape. Its types include extrusion die, embossing die, stamping die and end pressing die.

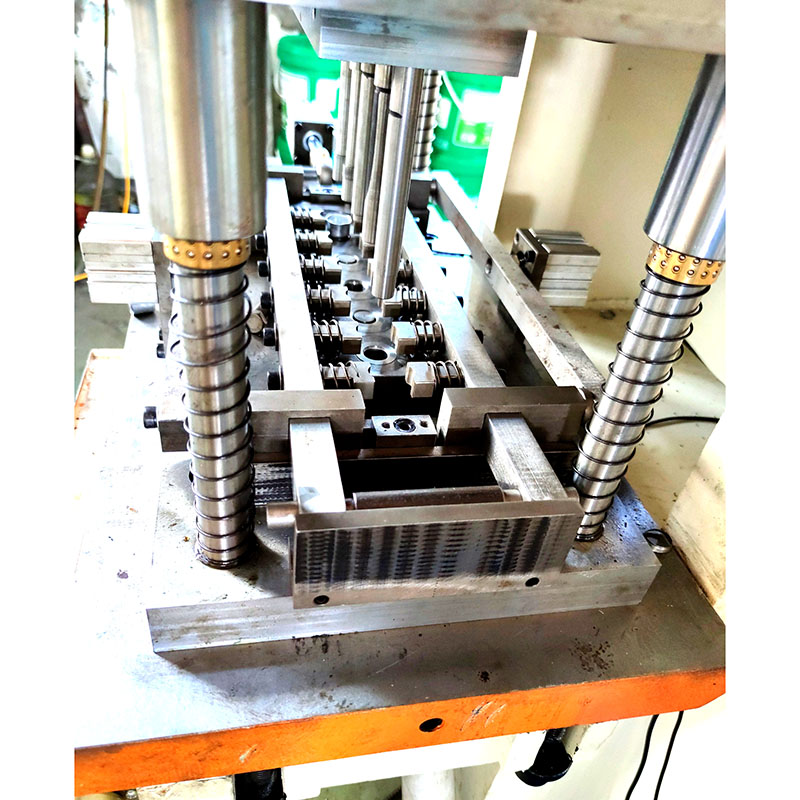

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Factory Free sample 80t Screen Mesh Stamping Punch Machine - Stamping Die – Daya , The product will supply to all over the world, such as: Victoria, Thailand, Venezuela, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.