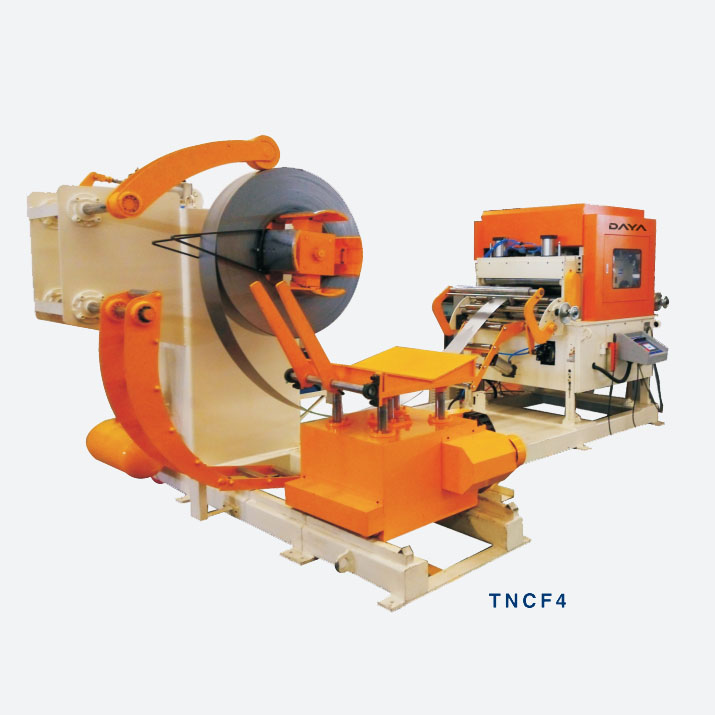

Manufactur standard 3 In 1 Precision Nc Servo Straightener Swing Feeder Machine W/Uncoiler - TNCF4-series 3IN INC Servo Feeder Machine – Daya

Manufactur standard 3 In 1 Precision Nc Servo Straightener Swing Feeder Machine W/Uncoiler - TNCF4-series 3IN INC Servo Feeder Machine – Daya Detail:

Characteristic

1. Leveling adjustment adopts electronic digital display meter reading;

2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment;

3. The height of feeding line is adjusted by motor driven elevator;

4. A pair of hollow roller blocking device is used for material sheet;

5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment);

6. Hydraulic pressing arm device;

7. The gear motor drives the feeding head device of the pressing wheel;

8. Hydraulic automatic feeding head device;

9. Hydraulic support head device;

10. The feeding system is controlled by Mitsubishi PLC program;

11. The precision of feeding is controlled by Yaskawa servo motor and high precision planetary servo reducer;

Introduction

Due to the continuous development of technology, punch and punch peripheral equipment are widely used. The application of punch peripheral equipment can improve production efficiency and reduce labor costs, so it is favored by manufacturers. The peripheral equipment of punch has split feeder, material rack, straightening machine, two in one straightening machine, three in one material rack correction feeder. Today we will briefly introduce the three in one feeding system.

1 Save space

The stamping production line includes material rack, leveling machine and feeding machine. If these three machines are independent, the volume of each machine is not small. Moreover, in order to ensure the normal production, there must be a material waiting area between the machine and the machine. Therefore, the floor area of the production line can be imagined. Generally, there is little space left after the equipment is wired, which makes it very inconvenient for operators to walk Benefit. The three in one feeder integrates the three machines into one. The fuselage is compact, and the floor area is reduced by more than half compared with the traditional separate independent stamping production line, so that the workshop space is fully utilized, and the operators also have sufficient operation space, which will not cause operation discomfort, and maximize the safety of stamping production.

2 Saving manpower and high working power

The three in one feeder only needs one person to complete the feeding, feeding, drawing, debugging, mold testing and other operations, and the time spent is not much. However, the traditional separate and independent type requires each set to be equipped with one person, and sometimes needs to help each other to complete the operation, which is not conducive to saving manpower and improving working power.

3 Simple operation and high precision

The three in one feeder adopts the computer control system. The function operation is completely concentrated on the console and control handle. One person can simply complete the operation, which is very humanized. The three in one feeder can set the feeding length arbitrarily, flatten the front end of the coil to facilitate the data to enter the roller, and the motor drives the pressing arm equipment to prevent the coil from loosening. The straightening and feeding machines are located on the same rack, and there is no interval between the bases, which fundamentally ensures the synchronization of their work. It can reduce the errors of feeding and rectifying, and reach the request of high precision, which is safe and stable.

4 High degree of initiative and wide applicability

The three in one feeder has compact structure, which is convenient for higher initiative production scheme and cooperation. From loading, uncoiling to leveling and feeding, a set of processes can be completed in a few minutes by one person. It is easy to operate and highly active. It is suitable for continuous stamping of various metal, stamping, electronics, electrical appliances, toys and auto parts.

5 Low failure rate and long life

Three in one feeder has low failure rate and long service life

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for Manufactur standard 3 In 1 Precision Nc Servo Straightener Swing Feeder Machine W/Uncoiler - TNCF4-series 3IN INC Servo Feeder Machine – Daya , The product will supply to all over the world, such as: Egypt, Poland, Riyadh, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.