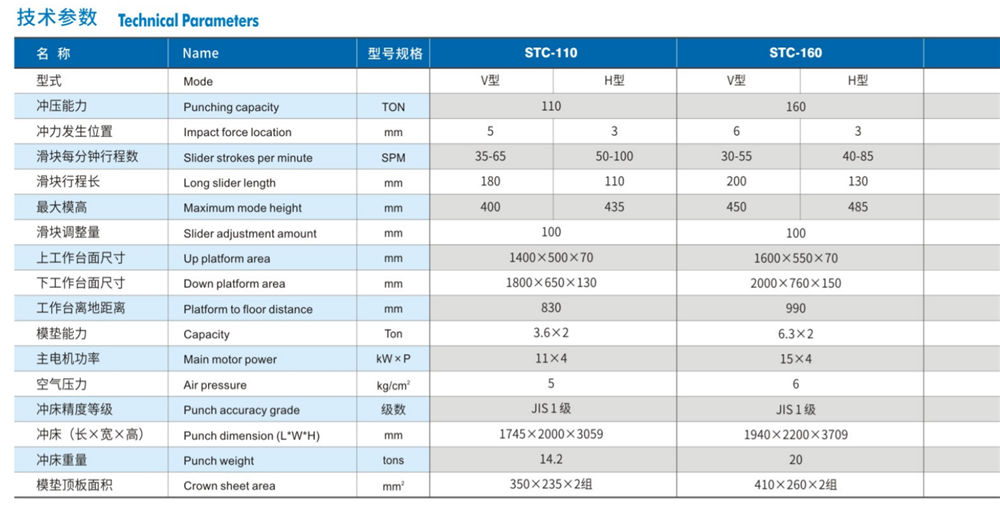

Ordinary Discount 110t Hot Die Forging Press Machine - STC Series C type “Open Double Point Crank Precision Punch Press” – Daya

Ordinary Discount 110t Hot Die Forging Press Machine - STC Series C type “Open Double Point Crank Precision Punch Press” – Daya Detail:

Main performance characteristics:

The rigidity (deformation) of the body and slider is 1/6000.

Use OMPI pneumatic dry clutch and brake.

The slider adopts two-corner six-sided guide path, and the slider guide adopts “high-frequency hardening” and “rail grinding process”: low wear, high precision, long precision retention time, and improved mold life.

The crankshaft is made of high-strength alloy material 42CrMo, which is 1.3 times stronger than 45 steel and has a longer service life.

The copper sleeve is made of tin-phosphorus bronze ZQSn10-1, whose strength is 1.5 times higher than that of ordinary BC6 brass.

The use of highly sensitive hydraulic overload protection device can effectively protect the service life of the punch and die.

Standard SMC pressure regulating valve, lubricator, air filter.

Optional mold cushion (air cushion).

Standard configuration

Advantages

Slide guide

Advantage 1: The slide rail adopts “high frequency quenching” and “rail grinding process”:

High frequency quenching: the hardness reaches above hrc48,

Rail grinding process: the surface finish can reach Ra0.4, the flatness is as high as 0.01mm/m2, which is generally 03mm / m2.

Advantages: small wear, high precision, long time to maintain precision and improve the service life of the die.

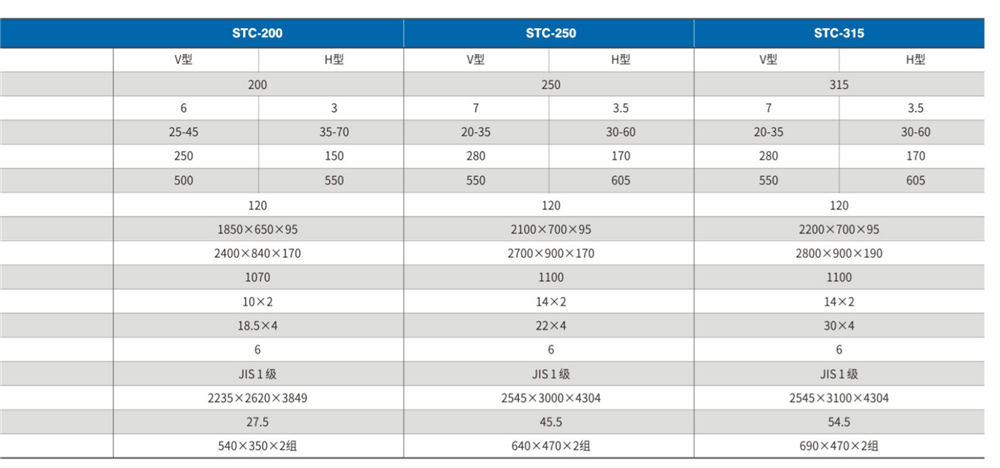

Worm gear

Advantage 2: Turbine with high adjustment of slide die adopts high strength copper alloy material: Tin Phosphorus Bronze (zqsn10-1)

Compared with the ball seat of nodular cast iron used by general factories

Advantages: the strength and wear resistance are improved correspondingly. The probability of seizure is greatly reduced in the process of die adjustment, Extended service life

Ball socket

Advantage 3: Ball seat material: sintered TM-3 copper alloy ball seat, ball socket of general manufacturer is nodular cast iron.

Advantages: the high-strength TM-3 copper alloy ball seat has a surface compressive strength of 1000kgf / C m2. In the process of stamping, the probability of seizure is greatly reduced and the service life is prolonged

Copper sleeve

Advantage 4: All copper sleeves of punch press are made of Tin Phosphorus Bronze zqsn10-1, and bc6 (zqsn 6-6-3) copper material is used by general manufacturers

Advantages: the strength is 1.5 times higher than that of bc6 copper, with high strength, small wear and long precision retention time

Thimble

Advantage 5: Sleeve ring, ring in contact with oil seal, ring “surface grinding” + “surface chromium plating (CR)” process

Advantages: the surface finish is between Ra0.4 and Ra0.8, it is not easy to leak oil when contacting with oil seal, and the surface is chromium plated (CR)

Process, hardness as high as hrc48 degrees, to ensure long-term use does not wear, oil seal service life is longer

Crankshaft

Advantage 6: The crankshaft is made of high strength alloy 42CrMo, and the crankshaft of general manufacturers is made of 45 steel

Advantages: the strength is 1.3 times higher than that of 45 steel, the service life is longer, and the probability of breaking crankshaft is greatly reduced (strictly through forging, heat treatment, flaw detection, processing, inspection, etc.) to ensure All kinds of quality problems in the production process of crankshaft are avoided to ensure the quality of crankshaft.

Tubing

Advantage 7: The standard machine open single point and open double point crank punch press, the standard oil pressure lubrication piping adopts Φ 6 (other manufacturers generally adopt Φ 4), medium and large punch press oil pressure lubrication pipe adopts Φ 8

Advantages: long pipeline, large diameter is not easy to block, break, ensure the safety of lubricating oil, smooth

Gear & drive shaft

Advantage 8: The gear shaft adopts high frequency quenching process to ensure long service life without wear and tear

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for Ordinary Discount 110t Hot Die Forging Press Machine - STC Series C type “Open Double Point Crank Precision Punch Press” – Daya , The product will supply to all over the world, such as: Leicester, Portland, Oman, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.