Popular Design for 260t C Type Double Crank Press Machine - C Frame Servo Press (STA series) – Daya

Popular Design for 260t C Type Double Crank Press Machine - C Frame Servo Press (STA series) – Daya Detail:

Main performance characteristics one:

Adopt high-strength body structure, small deformation and high precision

The slider adopts two-corner six-sided guide path, and the slider guide adopts “high-frequency quenching” and “rail grinding process”: low wear, high precision, long precision retention time, and improved mold life.

The crankshaft is made of high-strength alloy material 42CrMo, which is 1.3 times stronger than 45 steel and has a longer service life.

The copper sleeve is made of tin-phosphorus bronze ZQSn10-1, whose strength is 1.5 times higher than that of ordinary BC6 brass.

The use of highly sensitive hydraulic overload protection device can effectively protect the service life of the punch and die.

Standard Japanese SMC pressure regulating valve, lubricator, air filter.

Imported bearings and Japanese NOK seals are standard.

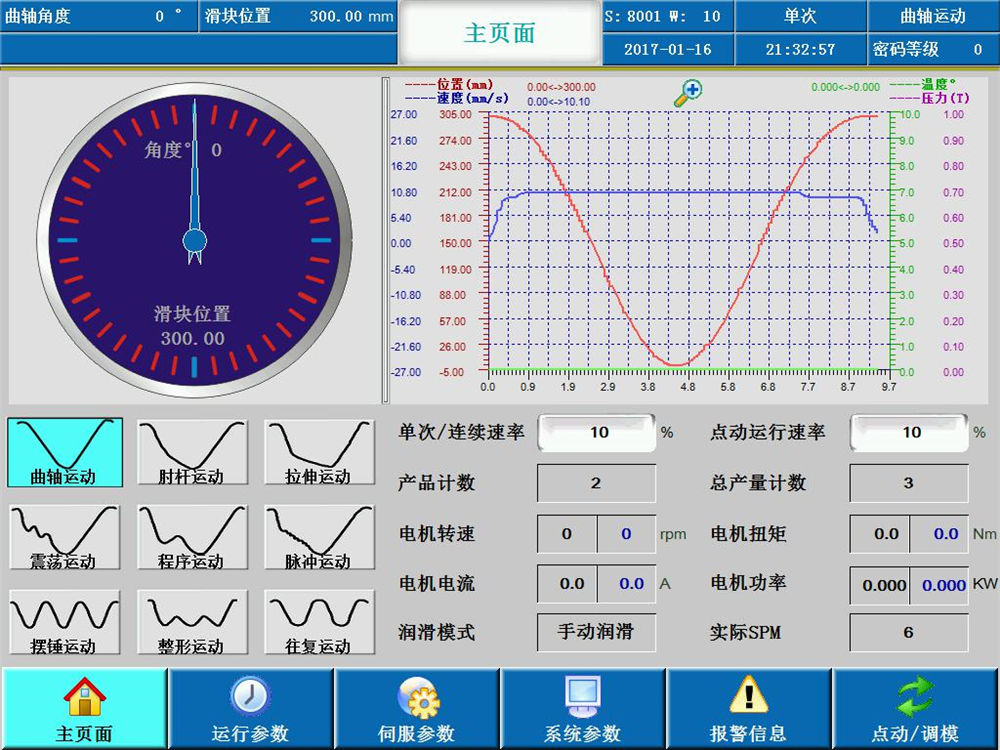

Standard Siemens touch screen

Optional mold cushion (air cushion).

Main performance characteristics two:

Built-in 9 processing modes, each product can select the most suitable processing curve for component processing,

So as to achieve high precision, high efficiency and high energy saving.

Compared with traditional punches, it has simple structure, high mechanical transmission efficiency and low maintenance cost.

According to the characteristics of the product/material, the punch forming speed can be reduced during material processing to achieve the best forming speed of the product/material. Thereby reducing vibration and stamping noise; improving product accuracy and prolonging the service life of molds.

According to different products, different heights are required, and the stroke of the punch can be set arbitrarily, which greatly shortens the stamping time and improves efficiency.

Built-in 9 processing modes

Standard configuration

Standard configuration

| Hydraulic overload protection device |

| Servo motor (adjustable speed) |

| Digital mold height indicator |

| Slider and mold balance device |

| Electronic cam switch device |

| Pre-cut counter |

| Air source connector |

| Two-degree fall protection device |

| Air blowing device |

| Independent control box |

| Reserved interface for wrong delivery detection device |

| Photoelectric safety protection device |

| Oil-collecting silencer |

| Electric grease lubrication device |

| Touch screen (pre-break, pre-load, total count) |

| Mold lighting device |

Optional Configuration

| Pneumatic mold pad device |

| Foot switch |

| Quick die change device (die lifter, die clamper |

| Or mold shifter) |

| Upper part punching device of slider |

| Feeder (air, mechanical and NC) |

| Leveling machine |

| Manipulator |

| Mold die lighting device |

| Rack |

| Thin oil lubrication device |

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Popular Design for 260t C Type Double Crank Press Machine - C Frame Servo Press (STA series) – Daya , The product will supply to all over the world, such as: South Africa, Vietnam, Austria, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!