PriceList for Compression Machine - Straight Side High Speed Press For Motor Stator And Rotor(HHD Series) – Daya

PriceList for Compression Machine - Straight Side High Speed Press For Motor Stator And Rotor(HHD Series) – Daya Detail:

Performance characteristics

1. The frame is made of high strength cast iron and high-precision integrated gantry structure, which prevents the opening problem of the fuselage under load, and realizes the processing of high-precision products;

2. Double axis center guide, four guide pillars guide the whole length, so even eccentric load can maintain excellent stamping accuracy and prolong the life of punch;

3. The forced lubrication and oil supply system of oil cooler are used to minimize the thermal deformation, which can be used for high-precision product processing;

4. Excellent dynamic balance device can reduce vibration and make the punch have the best precision and stability;

5. Specially equipped with electric mold adjusting function and mold height indicator to facilitate mold height adjustment;

6. The hydraulic sliding block locking system keeps the die height unchanged to ensure the product requirements;

7. Man machine interface microcomputer control, numerical fault monitoring system screen display, easy to operate;

| Technical parameter | ||||

| Specifications | Unit | HHD-125T | HHD-220T | HHD-300T |

| Press capacity | tons | 125 | 220 | 300 |

| Capacity occurring point | mm | 3.2 | 3.2 | 2 |

| Slider stroke length | mm | 30 | 30 | 30 |

| Slider strokes per minute | s.p.m | 150-700 | 150-600 | 100-450 |

| Working table area | mm | 1300*850 | 1900*950 | 2200*1000 |

| Material hole | mm | 1000*200 | 1300*250 | 1800*300 |

| Slide area | mm | 1300*600 | 1900*700 | 2200*900 |

| Mode height adjustment stroke | mm | 360-410 | 370-420 | 400-450 |

| The mode height adjustment motor | kw | 0.75 | 1.5 | 1.5 |

| Pass line | mm | 195±15 | 200±15 | 200±15 |

| Main motor | kw | 37 | 45 | 45 |

Advantages

Slide guide

Advantage 1: The slide rail adopts “high frequency quenching” and “rail grinding process”:

High frequency quenching: the hardness reaches above hrc48,

Rail grinding process: the surface finish can reach Ra0.4, the flatness is as high as 0.01mm/m2, which is generally 03mm / m2.

Advantages: small wear, high precision, long time to maintain precision and improve the service life of the die.

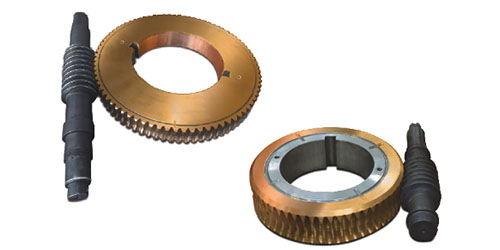

Worm gear

Advantage 2: Turbine with high adjustment of slide die adopts high strength copper alloy material: Tin Phosphorus Bronze (zqsn10-1)

Compared with the ball seat of nodular cast iron used by general factories

Advantages: the strength and wear resistance are improved correspondingly. The probability of seizure is greatly reduced in the process of die adjustment, Extended service life

Ball socket

Advantage 3: Ball seat material: sintered TM-3 copper alloy ball seat, ball socket of general manufacturer is nodular cast iron.

Advantages: the high-strength TM-3 copper alloy ball seat has a surface compressive strength of 1000kgf / C m2. In the process of stamping, the probability of seizure is greatly reduced and the service life is prolonged

Copper sleeve

Advantage 4: All copper sleeves of punch press are made of Tin Phosphorus Bronze zqsn10-1, and bc6 (zqsn 6-6-3) copper material is used by general manufacturers

Advantages: the strength is 1.5 times higher than that of bc6 copper, with high strength, small wear and long precision retention time

Thimble

Advantage 5: Sleeve ring, ring in contact with oil seal, ring “surface grinding” + “surface chromium plating (CR)” process

Advantages: the surface finish is between Ra0.4 and Ra0.8, it is not easy to leak oil when contacting with oil seal, and the surface is chromium plated (CR)

Process, hardness as high as hrc48 degrees, to ensure long-term use does not wear, oil seal service life is longer

Crankshaft

Advantage 6: The crankshaft is made of high strength alloy 42CrMo, and the crankshaft of general manufacturers is made of 45 steel

Advantages: the strength is 1.3 times higher than that of 45 steel, the service life is longer, and the probability of breaking crankshaft is greatly reduced (strictly through forging, heat treatment, flaw detection, processing, inspection, etc.) to ensure All kinds of quality problems in the production process of crankshaft are avoided to ensure the quality of crankshaft.

Tubing

Advantage 7: The standard machine open single point and open double point crank punch press, the standard oil pressure lubrication piping adopts Φ 6 (other manufacturers generally adopt Φ 4), medium and large punch press oil pressure lubrication pipe adopts Φ 8

Advantages: long pipeline, large diameter is not easy to block, break, ensure the safety of lubricating oil, smooth

Gear & drive shaft

Advantage 8: The gear shaft adopts high frequency quenching process to ensure long service life without wear and tear

Product detail pictures:

Related Product Guide:

We have our own product sales staff, style crew, technical group, QC staff and package staff. We now have strict high quality management procedures for each approach. Also, all of our workers are experienced in printing subject for PriceList for Compression Machine - Straight Side High Speed Press For Motor Stator And Rotor(HHD Series) – Daya , The product will supply to all over the world, such as: Tajikistan, Cologne, panama, Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.