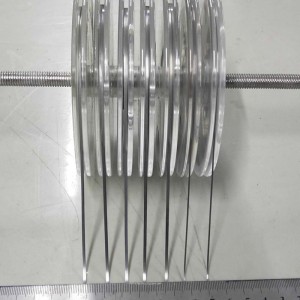

MO Molybdenum Strip

Product Name:Molybdenum Strip

Application:Stamping,Deep drawing

Technical Parameter

|

Elongation(δ) |

≥25% |

|

Yield Strength (RP0.2) |

600-9999MPa |

|

Tensile Strength(Rm) |

750-950MPa |

|

Vickers Hardness(HV) |

250-270 |

|

Warping |

4mm/2000mm |

|

Grain Size |

3.6-4.0 |

Size Specification

|

Width(mm) |

Thickness(mm) |

Length(m) |

|

10(±0.1) |

0.12(±0.02) |

≥100 |

|

12(±0.1) |

0.14(±0.02) |

≥100 |

|

14(±0.1) |

0.16(±0.02) |

≥100 |

|

16(±0.1) |

0.20(±0.03) |

≥70 |

Molybdenum application and science popularization

Molybdenum is a metal element, element symbol: Mo, English Name: molybdenum, atomic number 42, is a VIB metal. The density of molybdenum is 10.2 g / cm 3, the melting point is 2610 ℃ and the boiling point is 5560 ℃. Molybdenum is a kind of silvery white metal, hard and tough, with high melting point and high thermal conductivity. It does not react with air at room temperature. As a transition element, it is easy to change its oxidation state, and the color of molybdenum ion will change with the change of oxidation state. Molybdenum is an essential trace element for human body, animals and plants, which plays an important role in the growth, development and inheritance of human beings, animals and plants. The average content of molybdenum in the earth's crust is 0.00011%. The global molybdenum resource reserves are about 11 million tons, and the proven reserves are about 19.4 million tons. Because of its high strength, high melting point, corrosion resistance and wear resistance, molybdenum is widely used in steel, petroleum, chemical, electrical and electronic technology, medicine and agriculture. 3 refractory metal: application of molybdenum

Molybdenum occupies the first place in the iron and steel industry, accounting for about 80% of the total consumption of molybdenum, followed by chemical industry, accounting for about 10%. In addition, molybdenum is also used in electrical and electronic technology, medicine and agriculture, accounting for about 10% of the total consumption.

Molybdenum is the largest consumer of iron and steel, and is mainly used in the production of alloy steel (about 43% of molybdenum in total steel consumption), stainless steel (about 23%), tool steel and high speed steel (about 8%), cast iron and roller (about 6%). Most of molybdenum is directly used in steel-making or cast iron after industrial molybdenum oxide briquetting, while a small part is melted into ferromolybdenum and then used for steel-making. As an alloy element of steel, molybdenum has the following advantages: improving the strength and toughness of steel; improving the corrosion resistance of steel in acid-base solution and liquid metal; improving the wear resistance of steel; improving the hardenability, weldability and heat resistance of steel. For example, stainless steel with molybdenum content of 4% - 5% is often used in places with serious corrosion and corrosion, such as marine equipment and chemical equipment.