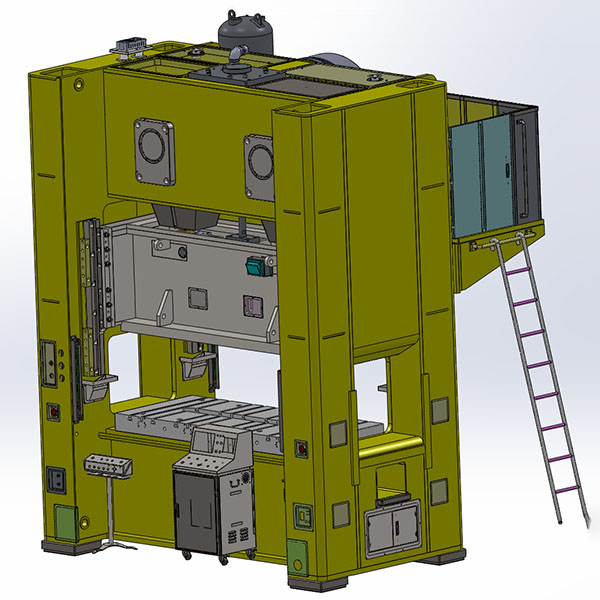

Semi Closed Single Crank Press (STB series)

Main performance characteristics:

Body rigidity (deformation) 1/6000.

Use OMPI pneumatic dry clutch and brake.

The slider adopts two-corner six-sided guide path, and the slider guide adopts "high-frequency quenching" and "rail grinding process", which has low wear, high precision, long precision retention time and improved mold life.

The crankshaft is made of high-strength alloy material 42CrMo, which is 1.3 times stronger than 45 steel and has a longer service life.

The copper sleeve is made of tin-phosphorus bronze ZQSn10-1, whose strength is 1.5 times higher than that of ordinary BC6 brass.

The use of highly sensitive hydraulic overload protection device can effectively protect the service life of the punch and die.

Standard SMC pressure regulating valve, lubricator, air filter.

Optional mold cushion (air cushion).

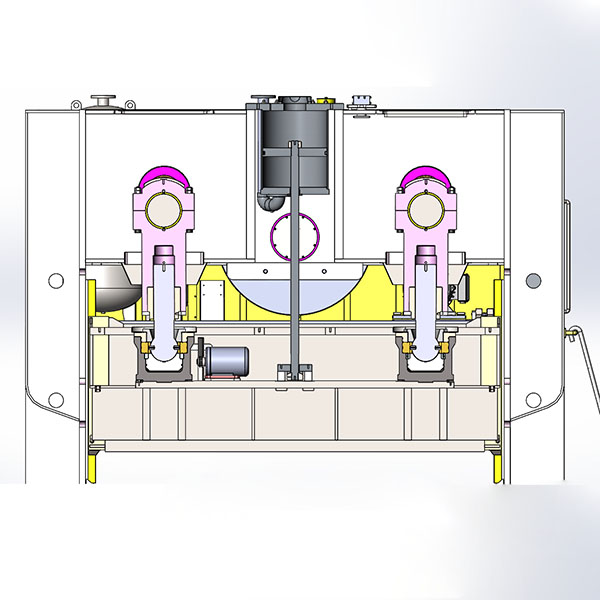

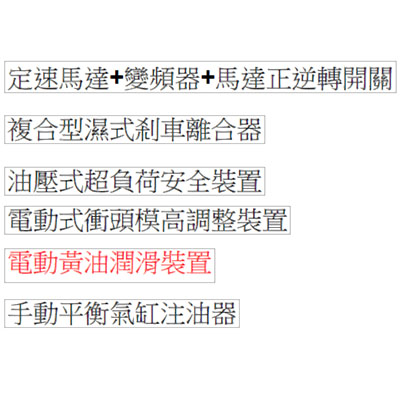

Standard configuration

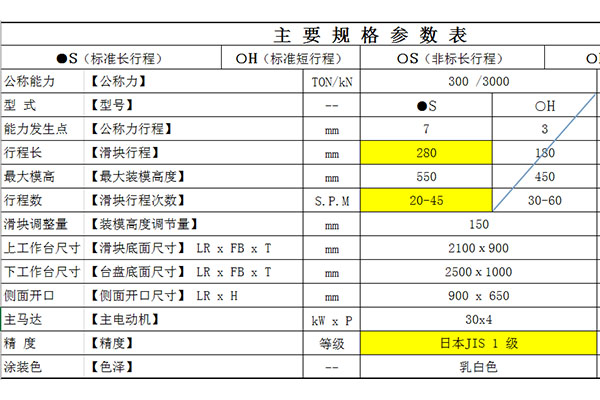

| Technical parameter | |||||||||||||

| Name | Specifications | STB-80 | STB-110 | STB-160 | STB-200 | STB-260 | STB-315 | ||||||

| Mode | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | |

| Press capacity | Ton | 80 | 110 | 160 | 200 | 260 | 315 | ||||||

| Impact force location | mm | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Slider strokes per minute | S.P.M | 35~80 | 80~120 | 30~60 | 60~90 | 20~50 | 40~70 | 20~50 | 50~70 | 20~40 | 40~50 | 20~40 | 40~50 |

| Slider stroke length | mm | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 280 | 170 |

| Max mold height | mm | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 520 | 600 |

| Slider adjustment amount | mm | 80 | 80 | 100 | 110 | 120 | 120 | ||||||

| Up platform size | mm | 560*420*70 | 650*470*80 | 700*550*90 | 850*630*90 | 950*700*100 | 1000*750*100 | ||||||

| Down platform size | mm | 760*550*90 | 900*600*110 | 980*880*140 | 1140*820*160 | 1500*840*180 | 1600*840*180 | ||||||

| Slider center to machine distance | mm | 280 | 305 | 405 | 415 | 430 | 430 | ||||||

| Platform to floor distance | mm | 830 | 830 | 900 | 995 | 1030 | 1030 | ||||||

| Shank hole | mm | Φ50 | Φ50 | Φ65 | Φ65 | Φ65 | Φ65 | ||||||

| Main motor power | KW*P | 7.5*4 | 11*4 | 15*4 | 18.5*4 | 22*4 | 30*4 | ||||||

| Slider adjust device | Manual / Electric | Electric | |||||||||||

| Air pressure | kg*cm² | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| Press accuracy grade | Grade | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | ||||||

| Press dimension(L*W*H) | mm | 1300*1890*3000 | 1420*1985*3200 | 1600*2200*3500 | 1750*2500*3900 | 2080*2895*4470 | 2100*2925*4550 | ||||||

| Press weight | Tons | 7.8 | 10.5 | 17.8 | 25.3 | 37 | 42 | ||||||

| Die cushion capacity | Ton | 3.6 | 6.3 | 10 | 14 | 14 | 14 | ||||||

| Die cushion Stroke | mm | 70 | 80 | 80 | 100 | 100 | 100 | ||||||

| Die cushion active area | mm² | 450*310 | 500*350 | 650*420 | 710*480 | 810*480 | 810*480 | ||||||

| NOTE:Our company is ready to carry out research and improvement work at any time. Therefore, the size design characteristics specified in this catalogue can be changed without further notice. | |||||||||||||

Standard configuration

| Hydraulic overload protection device |

| Manual slider adjustment device (below ST60) |

| Electric slider adjusting device (above ST80) |

| Variable frequency variable speed motor (adjustable speed) |

| Mechanical mold height indicator (below ST60) |

| Digital mold height indicator (above ST80) |

| Slider and mold balance device |

| Rotating cam controller |

| Crankshaft angle indicator |

| Electromagnetic counter |

| Air source connector |

| Two-degree fall protection device |

| Air blowing device |

| Mechanical shockproof feet |

| Reserved interface for wrong delivery detection device |

| Maintenance tools and toolbox |

| Main motor reversing device |

| Photoelectric safety protection device |

| Power outlet |

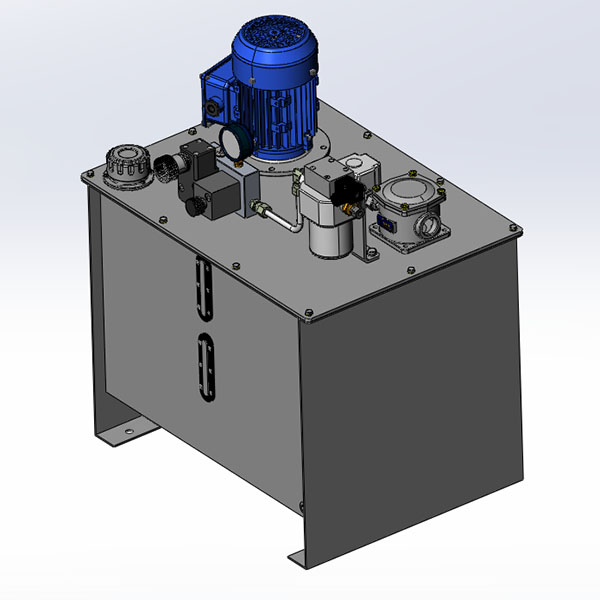

| Electric grease lubrication device |

| Touch screen (pre-break, pre-load) |

Optional Configuration

| Pneumatic mold pad device |

| Foot switch |

| Quick die change device (die lifter, die clamper |

| Or mold shifter) |

| Upper part punching device of slider |

| Feeder (air, mechanical and NC) |

| Leveling machine |

| Manipulator |

| Mold die lighting device |

| Rack |

| Thin oil lubrication device |

DAYA straight side double crank punch press

VS

Other straight side double crank presses

Daya press

Daya press: with platform and safety fence, convenient for clutch maintenance and change of cooling oil, main motor belt is loose and easy to adjust, and convenient for subsequent maintenance. Safer and more convenient.

Other press

Other press: Without maintenance platform. Clutch maintenance, replacement of cooling oil, loose adjustment of main motor belt, etc. which can only be completed with the assistance of forklift, which is not convenient for subsequent repair and maintenance. There are some potential safety hazards.

Daya press

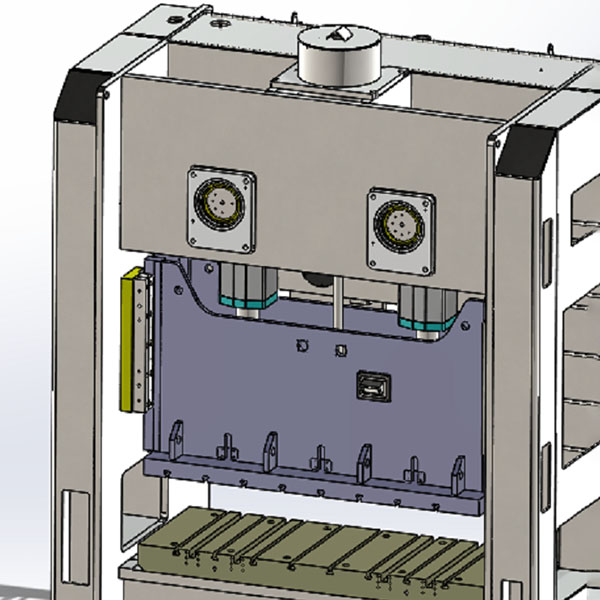

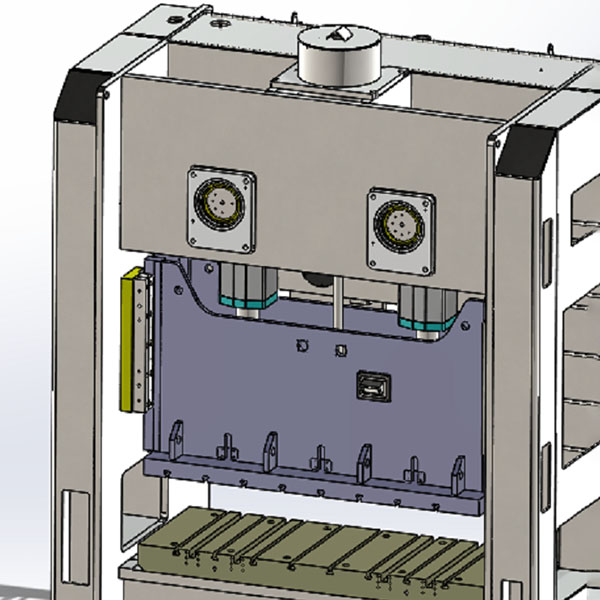

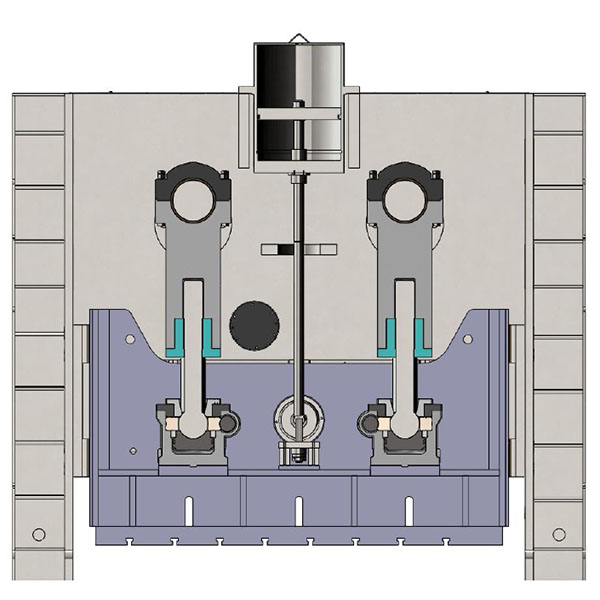

Daya press: Daya press adopts four corners and eight sides to surround the guide rail. In the stamping forming position, the slide guide rail is included by all the guide rails on the table body. This kind of guide rail has the characteristics of high stamping accuracy, strong anti eccentric load capacity, small rail wear and long precision retention time.

Other press

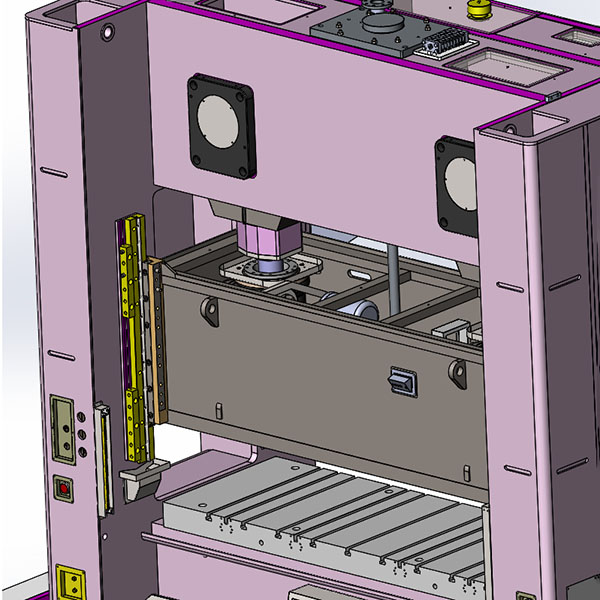

Other press: the guide rail with semi enclosed structure as shown in the right figure is adopted. During the stamping process, there is a section of guide rail exposed. During the stamping process, the slide guide rail is easy to tilt, with poor anti bias load capacity, large rail wear, short precision retention time and high maintenance cost.

Daya press

Daya press: the distance between the two points of force application is more than 60%; Advantages: the larger the distance between the two force application points, the greater the eccentric bearing capacity; the larger the distance between the two force application points, the higher the design cost.

Other press

Other press: the distance between the two points is generally less than 50%; Disadvantages: the smaller the distance between the two force application points, the smaller the eccentric bearing capacity. The guide rail is easy to tilt, the guide way is easy to wear, and the precision of guide rail is poor.

Daya press

Daya press: forced thin oil circulation system, energy saving, can be recycled, fan thermal performance is good, compared with grease lubrication can be increased by 5-10 beats per minute.

Other press

Other press: electric grease pump, grease can not be reused, no advantage of forced thin oil circulation system.

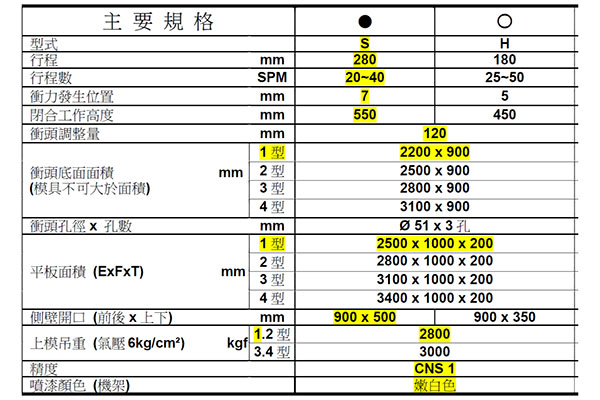

Daya press

Daya press: when the stroke length is the same, the forced thin oil circulation system has higher efficiency, compared with grease lubrication, it can increase 5-10 beats per minute. Strictly follow the Japanese JIS level 1 standard; the Japanese JIS level 1 standard is higher than the Taiwan CNS level 1 standard.

Other press

Other press:electric grease pump, grease can not be reused, no forced oil circulation system advantages. according to Taiwan CNS level 1 standard

Slide guide of Daya punch press

VS

other slide guides of punch

Daya press

Other press

Guide rail of Daya punch press

1.High frequency quenching process: hardness above hrc48;

2. Grinding process of guide rail: the surface finish can reach ra0.4-ra0.8 (mirror surface), flatness, parallelism and verticality within 0.005mm/ ㎡.

3.The machine tool has the advantages of small wear, high precision, long precision maintenance time, long service life and low energy consumption.

Other press guide railno quenching process; milling processing, surface roughness ra1.6-ra3.2, flatness, parallelism, perpendicularity more than 0.3mm / ㎡

Daya press crankshaft

VS

other press crankshafts

Daya punch press: the crankshaft is made of high strength alloy 42CrMo Advantages: the strength is 1.3 times higher than that of 45 steel, the service life is long, the wear resistance is good, the wear is small, and the precision is maintained for a long time.

Other presses: made of 45 steel, Disadvantages: low cost,the strength and wear resistance are not comparable to 42CrMo

Daya

Oil way of DAYA punch PRESS: Φ 8 is used for oil pressure lubrication piping.

Advantages: long pipeline, large diameter is not easy to block, break, ensure the safety of lubricating oil, smooth.

Other

Other presses: the oil pressure lubrication piping of press adopts Φ 6.